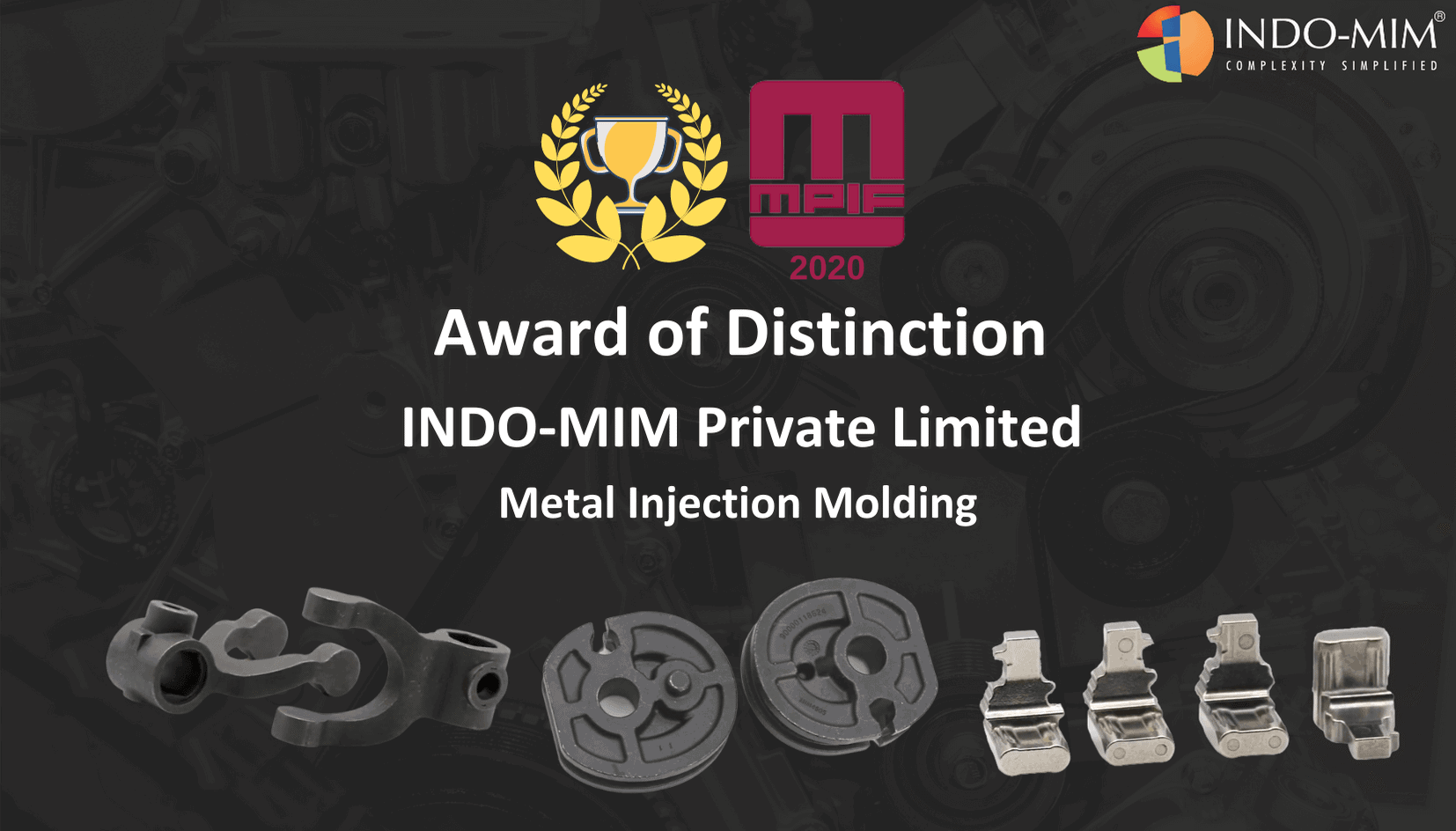

Metal Powder Industries Federation (MPIF) Design Excellence Award is one of the most prestigious platforms in the Powder Metallurgy (PM) & Metal Injection Molding (MIM) for recognizing achievement in this industry.

“INDO-MIM won 3 Award of Distinction this year at MPIF Conference

DISTINCTION AWARDS

- An Award of Distinction in the Automotive—Transmission Category for MIM components, has been given to Indo-MIM Pvt. Ltd. for a park lock lever manual override used in a vehicle handbrake. Made in a two-cavity mold using MIM-4605 and sintered on part-specific ceramic trays, the part replaced a machined component. The MIM part is heat-treated, has a density of 7.5 g/cm3, an ultimate tensile strength of 1550 MPa, and an apparent hardness of 35 HRC.

- An Award of Distinction has been given to Indo-MIM Pvt. Ltd. in the Automotive—Chassis Category for MIM components, for left- and right-hand-side cable guides used in a four-wheeler roof assembly. The MIM parts are made in a two-cavity mold and replaced expensive machined components. The MIM parts are made using MIM-4605, have a density of 7.5 g/cm3, and are heat-treated to an apparent hardness of 35 HRC. They have an ultimate tensile strength of 1550 MPa. As the parts are in constant exposure to the environment they need to be corrosion resistant and have a low friction coefficient. They therefore undergo a zinc-nickel coating process in a secondary operation.

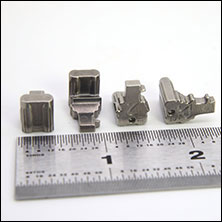

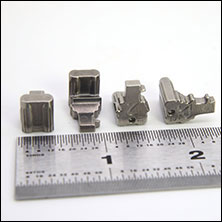

- An Award of Distinction in the Automotive—Engine Category for MIM components has been given to Indo-MIM Pvt. Ltd. for three min-flow setting devices used in the turbocharger of a four-wheeler vehicle. The parts are made using MIM-316L with a tunnel gate and four parts per shot. The parts are oriented horizontally in the mold, and most of the part is formed in the core while the chamfer is formed in the cavity. Double-line cooling channels provide optimum cooling, and this helps reduce the sink and void in the thickest portion of the part where coring was not acceptable. The MIM parts replaced components that were machined in multiple steps.