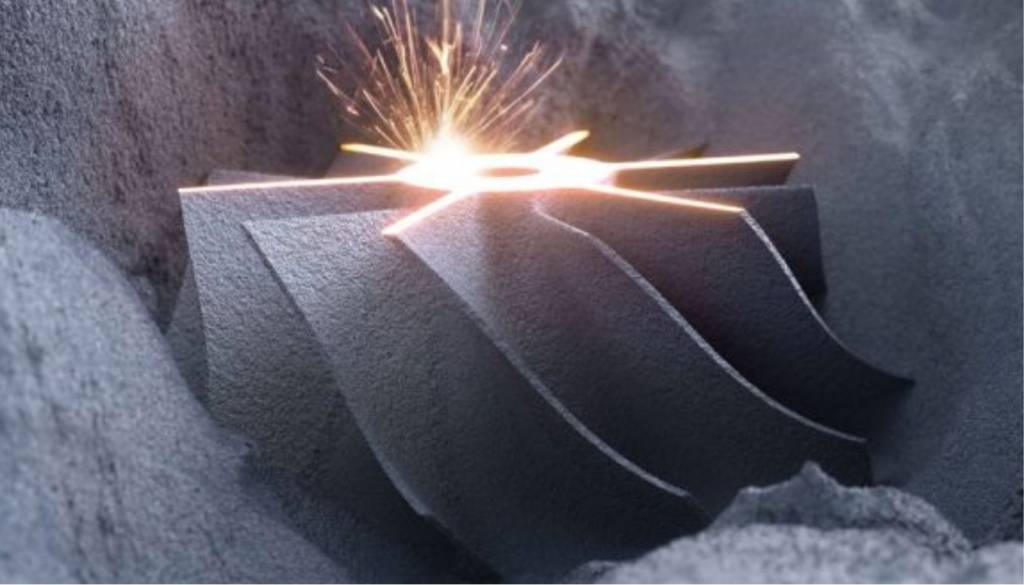

Fine Metal Powder for Additive Manufacturing

INDO-MIM hosts a world-class Vacuum-Melting Inert gas metal powder production facility with a production capacity of 1200 TPA. It is India’s largest inert gas metal powder production facility that produces powders for metal injection molding (MIM), additive manufacturing (Laser-bed fusion & Binder-Jet), thermal spray, and welding applications. Powder chemistry includes stainless steels, alloy steels, tool steels, nickel & cobalt superalloys. The atomizers are equipped with the anti-satellite unit which minimizes the satellite formation. This unique feature adds to the powder flowability which is critical for additive manufacturing and MIM applications. Our custom-built air classifiers ensure consistent PSD on every batch shipped. All the critical parameters are statistically monitored batch to batch for consistency.

Our Inconel-718 gas atomized powder is the first in the country approved by CEMILAC for airworthiness applications. Most of our standard powders are being consistently used on popular printer platforms. We also host multiple printers from leading manufacturers to continuously develop new powders on these printer platforms and fine-tune the quality of our powders.

Tightly controlled chemistry and particle size distribution (PSD) are the unique quality characteristics we guarantee on our powders. We produce powders with custom chemistry & PSD at affordable costs and at the shortest lead time in the industry. Many 3D printing service bureaus in the USA, Europe & India are already using our powders on a regular basis.

We will be introducing powders for thermal spray & cold spray coating applications for the purpose of wear resistance (sliding, abrasion, erosion), high-temperature oxidation resistance, anti-fretting, and dimensional Restoration. These metal powders will be suitable for High-Velocity Oxy-Fuel (HVOF), Plasma Spray, Flame(powder) spray, and Cold spray technologies. We have plans to expand the production to 2500 TPA in the next 3 years to address the growing market demand.