What is Binder Jetting? How does it works?

- Binder Jetting is a family of additive manufacturing processes. In Binder Jetting, a binder is selectively deposited onto the powder bed, bonding these areas together to form a solid part one layer at a time

- The materials commonly used in Binder Jetting are metals, sand, and ceramics that come in a powder form

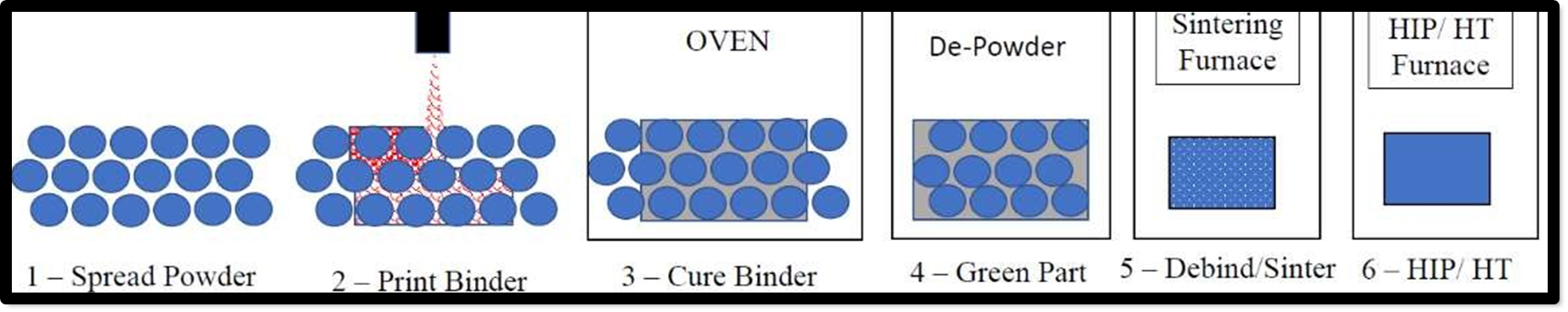

Binder Jetting Process:

- Step 1: Spread the Powder – To achieve consistent powder packing density

- Step 2: Jetting Binder – To wet the powder particles and to give shape to the components

- Step 3: Cure Binder – Produces enough green strength for handling the components

- Step 4: De-powdering – Removal of loose powders to extract green components

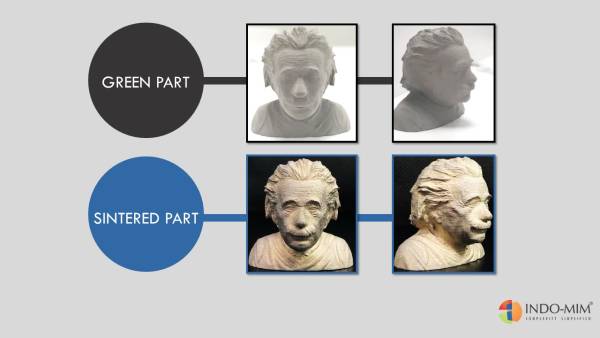

- Step 5: De-binding/Sintering – To remove extractable binders and to achieve final densification/ microstructure

- Step 6: Post Processing – To achieve desired metallurgical & mechanical properties

Why binder Jet ?

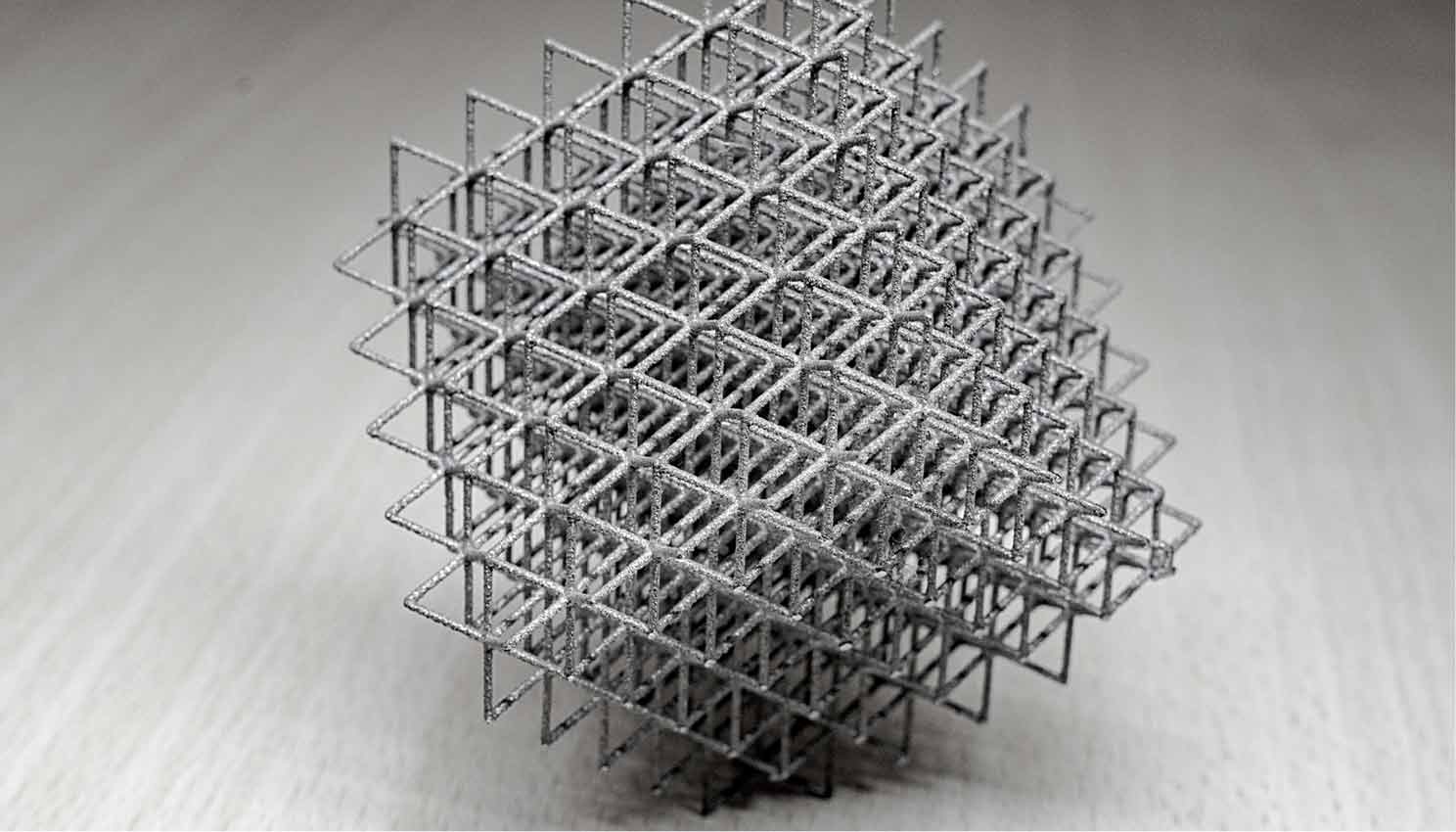

- Offers 360 degrees design freedom

- No support is required during the printing process.

- Ability to produce initial samples for design validation without having to invest on the tooling and lead time as compared to Metal Injection Molding(MIM) process (10 days vs 45 days with far less $$$$).

- Parts with extremely complex geometry require extremely intricate and complicated tools that are difficult to manufacture

Binder Jet materials which INDO-MIM Offer,

- SS-174ph

- SS-316

- SS-310

- M2 (Tool steel)

- S7

- 4605

- SS-420

- IN-625

- INDO-MIM produces gas-atomized powder in-house. We are aggressively working on developing various powders for Binder jet 3d printing technology.

Example of Binder Jetting Printed Parts

INDO-MIM is handling 80+ materials for different applications. We will produce customized components. Willing to collaborate for new product development. We have an In-house testing facility for characterization and will provide a Competitive solution in a shorter lead time.